What is Freon Keeper?

Freon Keeper is a refrigerant leakage detection system. It can be installed to refrigeration units to detect its refrigerant leakage at early stage. Our self-developed system "Freon Keeper" detects refrigerant leakage at 10% by using ultrasonic.

Benefit on an earlier detection of refrigerant leakage

01

Reduction of

leakage amount

You can contribute to the prevention of global warming because of reducing refrigerant leakage from refrigeration equipment.

02

Cost saving

You can reduce electricity and repair costs due to avoid continuous operation of refrigeration equipment that is short of refrigerant.

03

Stable operation of equipment

You can prevent a loss of product stocks and sales opportunities, furthermore, extend the lifetime of the equipment.

Characteristic of Freon Keeper

Characteristic of Freon Keeper

Early detection of refrigerant leakage by ultrasonic detection system

Early detection of refrigerant leakage by ultrasonic detection system

Early detection of refrigerant leakage by ultrasonic detection system

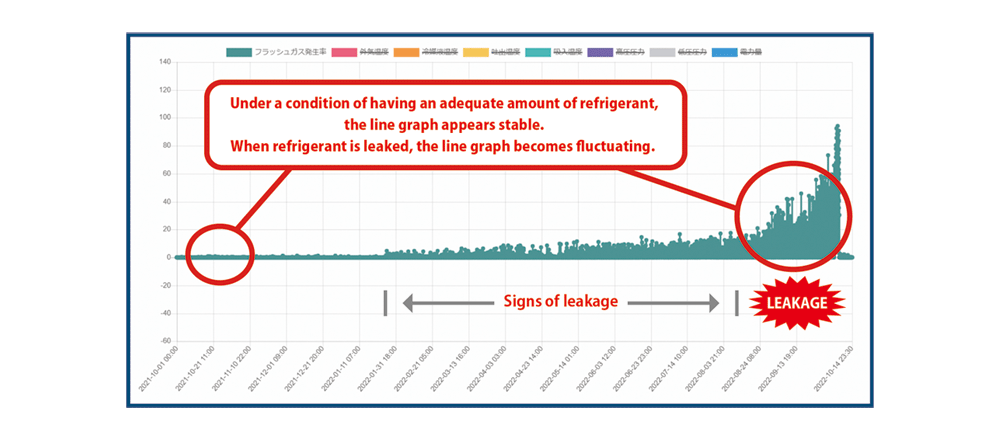

When refrigerant starts leaking, liquid refrigerant which is circulating in the refrigeration units produces flash gas. Ultrasonic detection system can immediately detect this flash gas. You can notice refrigerant leakage at early stage before having the temperature sign.

If you continue to use the refrigeration equipment with the refrigerant leaking, the cooling capacity will be insufficient and the power consumption will increase. Freon Keeper is the only solution to this risk.

temperature

Small amounts of leakage

One tiny bubble that is difficult to perceive by human eyes appears in the sight glass. Freon Keeper can detect the leakage as early as at this stage.

temperature

Large amounts of leakage

Large amount of leakage and the increased number of bubbles appear in the sight glass. This left photo shows about 50% of leakage.

IoT transformation for refrigeration equipment

IoT transformation for refrigeration equipment

IoT transformation for refrigeration equipment

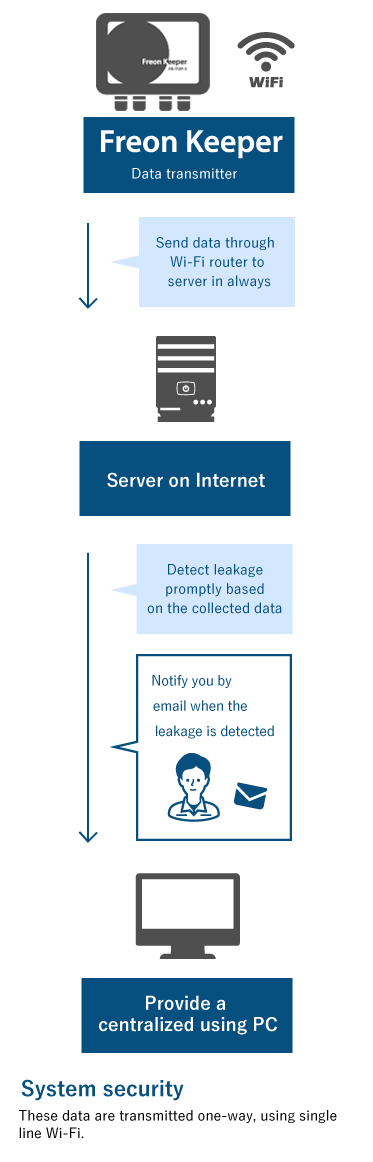

Our unique system detects refrigerant leakage by collecting various data, such as refrigerant pressure and temperature, electric current and ambient temperature. And Freon Keeper automatically sends them to the server every 10 minutes. This provides a centralized and real-time management system of the refrigeration equipment in various stores using PCs 24 hours/365days.

- How Freon Keeper works with IoT service

- Management portal

Collected data such as outside temperature and liquid refrigerant temperature are displayed in graph form and tabular form. CSV data can be downloaded.

(Only Japanese version is available at the moment. English version is planned to be launched.)

Saving power and repair costs

Saving power and repair costs

Saving power and repair costs

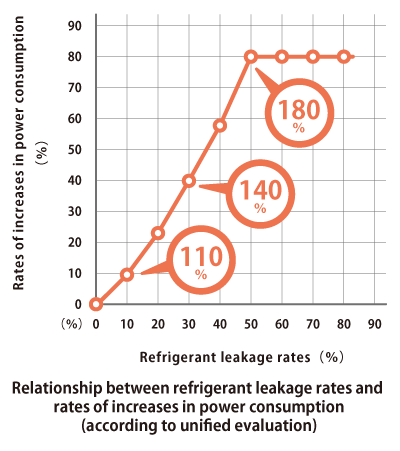

Refrigerant leakage significantly increases power consumption of refrigeration equipment. Separate-type showcases, which are often used in supermarkets, leaks approximately 16% of refrigerant per year on average. (Source: Based date from Ministry of Economy, Trade and Industry in Japan)

If the refrigeration equipment is continuously operated with over 10%, 30% and 50% of refrigerant leaked, it reduces the operating efficiency of the equipment and results that power consumption increases respectively 10%, 40% and 80%.

(Source: Survey commissioned work from Ministry of the Environment in Japan on understanding the effects of global warming countermeasures on Freon leak detection systems that utilize IoT technology (2021))

Because refrigerant leaks very slowly in many cases, you will be consuming an excessive amount of power (up to 80%) until you realize that a leak has been happening.

Specialized companies almost don’t realize these facts. Freon Keeper can reduce following costs* by detecting an about 10% of leakage early.

*They are calculated from the amount of filled refrigerant.

- Amount of refrigerant leakage

- Separate show case

- 16%

- Condensing unit

- 13%

- Refrigeration unit

- 17%

- Air conditioner for light commercial

- 3%

- Air conditioner for facilities and factories

- 5%

- Gas heat pump air conditioner

- 5%

(Source: Data released by the Ministry of Economy, Trade, and Industry in Japan)

Saving electricity cost

You can save power costs maximum 45% if Freon Keeper detects refrigerant leakage early.

You can save power costs maximum 45% if Freon Keeper detects refrigerant leakage early.

¥1,937,100/Year

¥1,937,100/Year

【Electricity cost in case of 50 % refrigerant leakage in a year】

18.0 kW (per unit) × 1.8* × 0.65*× 24 hours × 27 yen (1kW/h) = 13,646.88 yen/day

*1.8=Electric energy increased by 80%

*0.65=Equipment utilization rate

13,646.88 yen × 365 days = 4,981,111.2 yen/year …A

【Electricity cost when there is 10% refrigerant leakage with Freon Keeper installed】

18.0 kW (per unit) × 1.1* × 0.65× 24 hours × 27 yen (1kW/h) = 8,339.76 yen/day

*1.1=Electric energy increased by 10%

8,339.76 yen × 365 days = 3,044,012.4 yen/year …B

A - B = 4,981,111.2 – 3,044,012.4 ≒ ¥1,937,100

A - B = 4,981,111.2 – 3,044,012.4 ≒ ¥1,937,100

*Average per store (10 supermarkets in Tohoku region that own an average of 7.4 refrigerators.)

Saving repair cost

You can save repair costs by detecting 10% refrigerant leaks and repairing at an early stage.

You can save repair costs by detecting 10% refrigerant leaks and repairing at an early stage.

¥159,500/Year

¥159,500/Year

【 Repair cost in case of 16 % refrigerant leakage in a year】

Leakage amount 75 kg: 75 kg × 4,500 yen (R-404A price/kg) = 337,500 yen

Top up service fee: 75kg × 500 yen = 37,500 yen

Leakage inspetion and repair fee: 3 man-hour/8 hours × 35,000 yen = 105,000 yen

Adjustment fee: 4 times × 50,000 yen = 200,000 yen

Sundry expenses: 68,000 yen

Total: 337,500 + 37,500 + 105,000 + 200,000 + 68,000 = 748,000 yen/year…C

【Repair cost in case of 10 % refrigerant leakage in a year】

Leakage amount 46 kg: 46 kg× 4,500 yen (R-404A price/kg) = 207,000 yen

Top up service fee: 46kg × 500 yen = 23,000 yen

Leakage inspetion and repair fee: 3 man-hour/8 hours × 35,000 yen = 105,000 yen

Adjustment fee: 4 times × 50,000 yen = 200,000 yen

Sundry expenses: 53,500 yen

Total: 207,000 + 23,000 + 105,000 + 200,000 + 53,500 = 588,500 yen/year…D

C - D = 748,000 - 588,500 = ¥159,500

C - D = 748,000 - 588,500 = ¥159,500

※Average per store (10 supermarkets in Tohoku region that own an average of 7.4 refrigerators.)